Cast vs heat

Cast vs. Heat-Laminated Polykraft Jacketing: Making the Right Choice for Insulation Protection

Aluminum jacketing used for insulation protection is generally produced using two primary methods. The difference between these techniques lies in the lamination process and the overall quality and performance of the final product. Below, we compare the two most common production methods for Polykraft aluminum jacketing:

1. Heat-Laminated Polykraft

In this method, pre-coated polyethylene Kraft paper is introduced into the production line and bonded to preheated aluminum sheets. Since the lamination between the paper and aluminum is not performed simultaneously, the polyethylene does not sufficiently penetrate the microscopic irregularities of the aluminum surface. As a result, the bond is weaker, and the Polykraft layer tends to delaminate from the aluminum, especially when exposed to alkaline moisture or humid conditions over time.

2. Cast-Laminated Polykraft

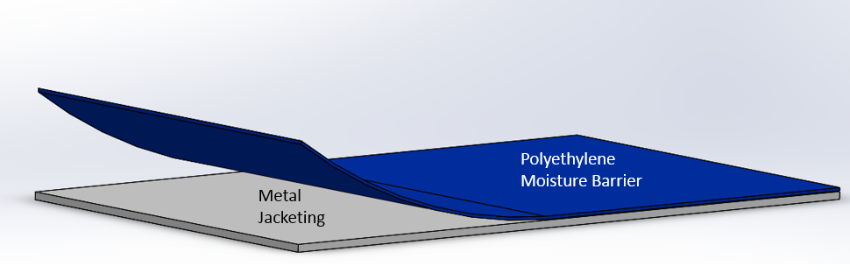

This more advanced method involves directly casting molten polyethylene between heated aluminum sheets and Kraft paper in a single, continuous step. The process ensures strong and uniform adhesion between the layers. Due to deeper penetration of molten polyethylene into the aluminum surface, the final product demonstrates significantly higher resistance to moisture, delamination, and environmental stress—making it more durable and reliable in harsh industrial conditions.

At E.G.P., our continuous casting process ensures exceptional quality in aluminum jacketing. This method results in a more uniform structure, improved mechanical strength, and better surface finish—making our jacketing products more reliable and durable for industrial insulation protection.

Galvanic Corrosion and the Importance of Proper Moisture Barriers

A persistent challenge in industrial insulation projects is the risk of corrosion under insulation (CUI), particularly caused by direct contact between moisture and the aluminum jacketing or the underlying substrate (such as steel pipes or tanks). When insulation becomes wet, soluble salts act as electrolytes, creating a galvanic cell between the aluminum and the base metal. This leads to electrochemical corrosion over time.

To prevent such failures, aluminum jacketing must include an appropriate moisture barrier—such as Polysurlyn Moisture Barrier (PSMB) or Polykraft—which serves to reduce moisture ingress and protect against galvanic activity.

Laboratory Simulation of CUI

In a simple lab experiment, a 30 cm steel pipe is insulated with calcium silicate and wrapped in aluminum jacketing. The lower part of the pipe is immersed in water, and copper wires are attached to both the pipe and the jacketing to measure galvanic current. If no moisture barrier exists, or if it is poorly applied, water absorbed by the insulation triggers the formation of a galvanic cell, initiating corrosion.

The results clearly indicate that the structure and quality of the moisture barrier play a crucial role in minimizing galvanic corrosion and extending the service life of the insulation system.

| Sample |

Sample Description |

Durability Period |

| 1 | Embossed aluminum, 0.6 mm thick, with 15-micron epoxy acrylic coating |

4 weeks |

| 2 | 3 weeks | |

| 3 | Plain aluminum, 0.4 mm thick, without coating | 1 week |

| 4 | 4 weeks | |

| 5 | Color-coated plain aluminum, 0.4 mm thick, with heavy polykraft lining* |

- |

| 6 | - | |

| 7 | Plain aluminum, 0.4 mm thick, with 15-micron epoxy acrylic coating | 3 weeks |

| 8 | 14 weeks | |

| 9 | Plain aluminum, 0.4 mm thick, with light polykraft lining** | 15 weeks |

| 10 | - | |

| 11 | Plain aluminum, 0.8 mm thick, with 15-micron epoxy acrylic coating | 1 weeks |

| 12 | 1 weeks | |

| 13 | Laminated plain aluminum, 0.4 mm thick, with 15-micron epoxy acrylic coating | 1 weeks |

| 14 | 10 weeks | |

| 15 | Embossed aluminum, 0.4 mm thick, with light polykraft lining | - |

| 16 | 9 weeks | |

| 17 | Plain aluminum, 0.4 mm thick, with 15-micron epoxy acrylic coating | 3 weeks |

| 18 | 3 weeks |

*heavy polykraft: 50 lb kraft paper + 75-micron polyethylene

**light polykraft: 40 lb kraft paper + 25-micron polyethylene

Conclusion from Comparative Testing

Comparative lab tests performed on aluminum samples with various epoxy-acrylic coatings and polykraft linings confirm that aluminum jacketing equipped with Polykraft offers superior resistance to corrosion. This durability is significantly enhanced when cast lamination is used, as the uniform polyethylene layer provides stronger adhesion and more effective protection against moisture ingress and galvanic activity.