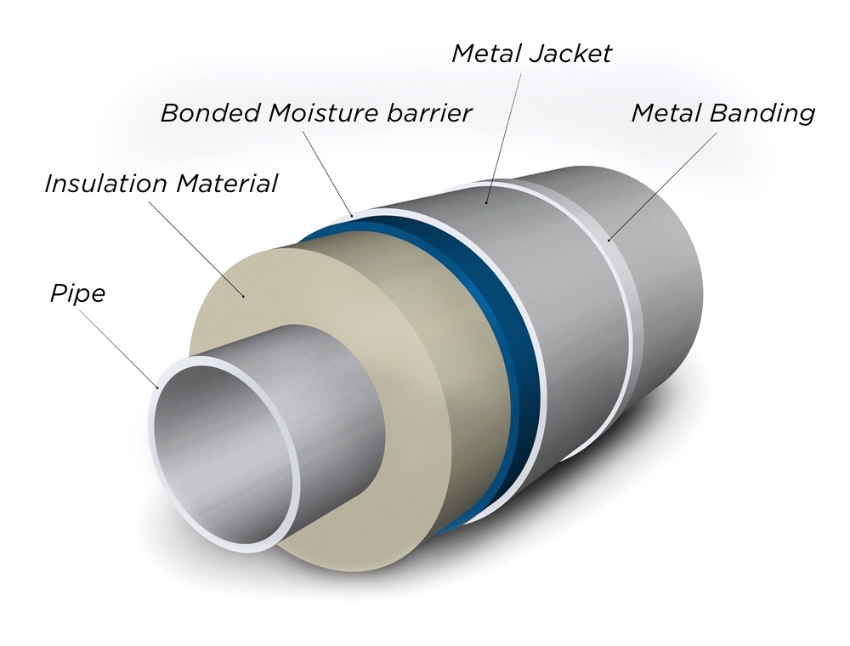

Why Polysurlyn?

Simple, low cost, and effective protection against metal jacket and pipe corrosion.

Provides a barrier to crevice or pitting corrosion on the inner jacket surface in cold and hot pipe/tank applications. Provides a barrier to galvanic corrosion of jacket or pipe in hot applications. Metal jacketing and water don’t mix.

Crevice corrosion that occurred when Polykraft moisture barrier, was used.

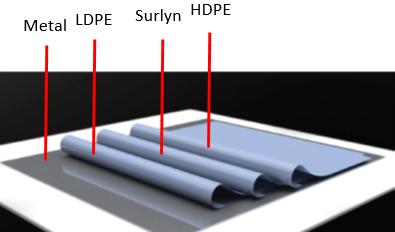

When water is present and touching the metal jacket, corrosion can and does occur. This can happen in all applications (hot, cold, rooftop, industrial, commercial, etc.) and with all insulation types. Polysurlyn is manufactured from 3 layers of film:

- 25-micron high-density polyethylene

- 25-micron Surlyn®

- 25-micron low-density polyethylene

, with each layer carefully selected to yield optimum performance.

This multilayer film is laminated to the interior side of ITW’s aluminum and stainless steel jacketing using precise pressure and heat. Use of 75-micron thick three layer Polysurlyn Moisture Barrier, (PSMB) film avoids the pinholes prevalent in standard single layer Polykraft. Polysurlyn superiority: In 2005, after careful analysis, ITW Insulation Systems changed from Polykraft to PSMB due to the superior performance and water resistance of the multilayer Polysurlyn film.

The Advantage of Polysurlyn:

Following extensive evaluations in recent years, Ebdaagaran Padide (E.G.P.) has decided to use PSMB (Polysurlyn Moisture Barrier) instead of Polykraft. This decision was made due to the high performance of the three-layer Polysurlyn film, its superior moisture resistance, and its effectiveness in preventing corrosion-related damage in industrial installations.

Polysurlyn benefits:

- Minimal water absorption compared to kraft paper

- Will not deteriorate, discolor or shred when exposed to water

- Provides abrasion resistance during installation

- Long term durability and resistance to a wide range of environmental contaminants

- Metal jacketing with PSMB has an ASTM E84 flame/smoke performance of ≤25/50

- Aluminum jacketing with PSMB complies with ASTM C1729, Class A

| POLYSURLYN | POLYKRAFT |

|

Co-extruded 3-layer film with 75-micron thickness |

Plastic film is a single layer |

|

No pin holes, better moisture retarder, properties |

Pin holes allow moisture to contact the metal |

|

No water absorption, no possibility of moisture contact with metal |

Exposed surface of Polykraft is paper which readily absorbs water |

PSMB is a minimal investment or “insurance” to protect valuable metal jacketing and pipe

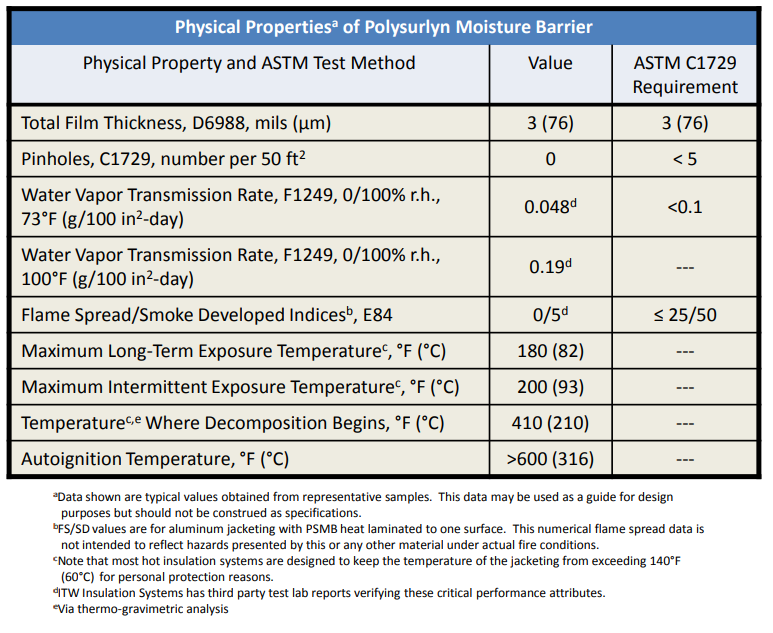

Physical Characteristics of Polysurlyn:

- Three layer film with total thickness of 3 mils (0.75 mm)

- Zero pinholes

- Water Vapor Transmission Rate (WVTR) ≤.21 grams per 100 square inches (.065 sq meters) per day

- Auto ignition temperature of about 600°F (3l6°C). Kraft paper is approximately 450°F (233°C)

BELOW ARE DEFINITIONS ACCORDING TO THE ASTM C1729 STANDARDS FOR ALUMINUM JACKETING FOR INSULATION:

MOISTURE RETARDER (also known as moister barrier):

layer of plastic film or other material applied to the inner side of metal jacketing to inhibit jacket corrosion by interfering with the formation of a galvanic cell between the dissimilar metal of the pipe and jacket or by preventing crevice corrosion.

POLYKRAFT: multilayer composite film used as a moisture retarder on metal jacketing consisting of at least one layer of minimum 40 LB kraft paper and one or more layers of plastic film, usually polyethylene at a minimum thickness of 1.5 mils.

POLYSURLYN: a multilayer film used as a moisture retarder on metal jacketing consisting of at least one layer of acid copolymer, surlyn and one or more layers of other polymers, usually polyethylene.

| PROPERTY | PAINT | POLYKRAFT | POLYSURLYN |

|

Moisture Barrier Description |

1 layer at ̴0.7 mils thick |

1 layer of 1.5 mil thick PE film with Kraft paper backing |

3 layer polymer film with total thickness of 3 mils (1 mil LDPE, 1 mil Surlyn*, and 1 mil HDPE) |

|

Pinholes per 50 ft2 via ASTM C1729 Method |

>19 |

16 |

0 |

|

Water Resistannce WVTR (g/100 in2-day) |

Unknown |

Excellent <0.05 |

|

| Toughness |

Easily scratched |

Paper easily damaged |

Strong and scratch resistant |

| Flammability | Good |

Unknown but exposed paper surface has autoignition temp of~450°F (232°C) |

Tested on aluminum using ASTM E84 yielding flame/smoke of 0/5 Autoignition temp for polysurlyn is >600°F (316°C |

E.G.P., as a pioneer in the insulation protection industry, recommends using a 75-micron Polysurlyn layer instead of Poly-Kraft backing in metal jacketing systems.

EBDAAGARAN PADIDE

(P.J.S.)

EBDAAGARAN PADIDE

(P.J.S.)